Innovation Ushers In New Era Of Plant-based Flavors, Applications and Products

Industry Trends, Ingredient Trends, Non-dairy Ingredients

New Products Satisfy a New Kind of Consumer focused on Plant-based Options

Bluegrass Ingredients On-site Hiring Event | March 19 | Glasgow, KY.

The concept of “agile” is used across many industries, particularly in the software development and manufacturing sectors. But what exactly do organizations mean when they say they are agile? And how does that approach benefit customers and end consumers?

Ultimately, being agile comes down to the ability to create and respond to change.

While its origins are in the software development world, agile processes are purpose-built for competitive industries like the food manufacturing space, where small changes can make or break in the eyes (or tastes) of a consumer.

Agile manufacturing companies prioritize processes, tools and training that allow them to quickly respond to customer needs and market shifts while keeping costs and quality in check. They focus on identifying and addressing challenges and opportunities early to avoid downstream complications. They utilize incremental and iterative product development – creating viable products at each step that adapt existing solutions and can be enhanced with each new version. Agile tactics like “sprints” and “scrums” allow teams to move fast on updates and align on goals and needs.

At Bluegrass Ingredients, agile principles are integrated into our service model – Agile Ingredient Innovation.

That model is the foundation of how we work and innovate, how we connect and collaborate with customers and how we work to advance flavor, form and function in the food industry.

We deliver dreams daily through our Agile Ingredient Innovation model. Every day, our team of R&D, culinary and quality experts leverage agile methods to support entrepreneurs and organizations dreaming of that perfect food.

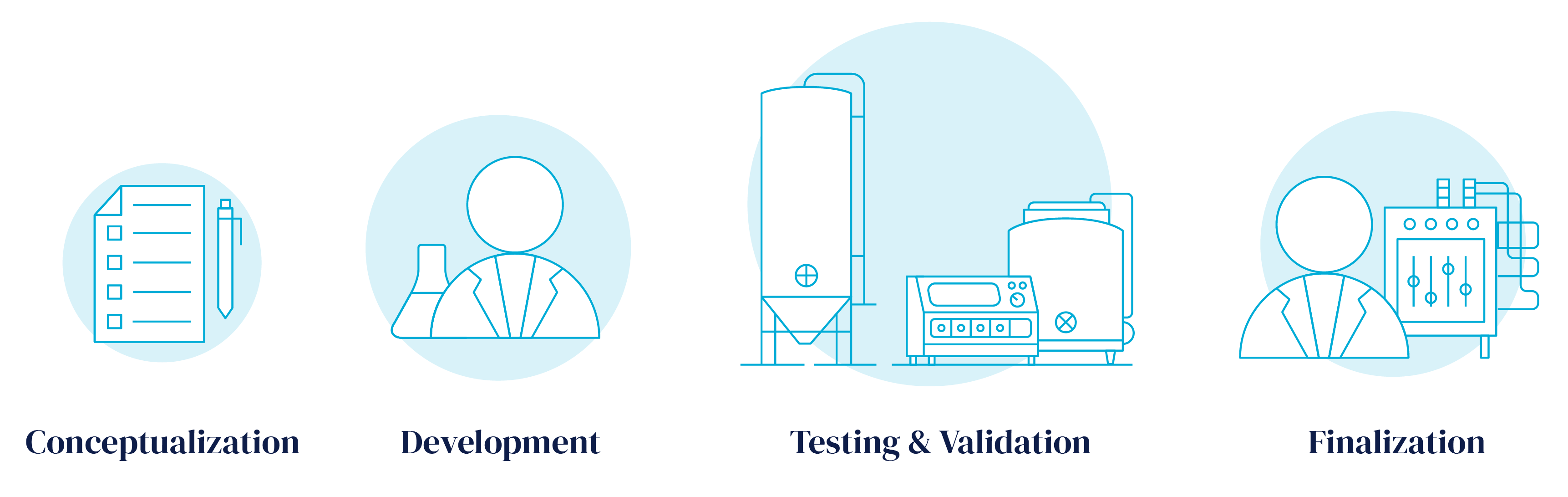

Our Agile Ingredient Innovation model means our development team designs and adjusts ingredients to meet our customers’ requests and expectations. It typically starts with a ‘new product number’ — NP-1. Then the collaboration begins. Iteration NP-1 is designed, presented, evaluated, tweaked and presented again as NP-2. The agile process continues, with potential in each new iteration.

Our NP pipeline can reflect NP-5, NP-8, NP-12. We proactively partner with customers to help them realize their food dreams and business goals.

The approach doesn’t come without its challenges. There’s something to be said for collecting all the data and formalizing processes before beginning to iterate – just ask any senior food scientist. If it takes dozens of iterations to get to a finished product, is that really the best approach?

For Bluegrass Ingredients, the answer is yes. Those iterations prompt inspiring new ideas and innovations that can redefine current and future offerings.

There’s no limit to the potential that exists in those iterations.

At the same time, waiting for a complete plan before taking action takes time and can curtail innovation and collaboration. It creates openings for competitors to work faster and for consumer tastes to shift.

The reality is, an agile food manufacturing approach can drive significant benefits on specific projects and across the entire relationship between customers and suppliers.

Developing and refining new products and ingredients takes time. And it’s worth doing it right. During that development process, however, things can change and consumer preferences can shift. Industry M&A activity can shake up supply chains. Agile processes allow for rethinking assumptions and tweaking individual components of a larger initiative in real time, which creates greater adaptability and

a better aligned end product.

Creating space to iterate and rapidly innovate really can deliver the best results. Moving the needle on an individual ingredient through refinement, testing and tasting ultimately improves flavor, form and function. It creates a better end product. Just as crucially, those learnings can be applied to future ingredients and projects. The collaboration and tighter working relationships that come from this partnership will carry over as well.

Project managers and quality control experts spend a lot of time debating what exactly constitutes agile and lean manufacturing processes. In truth, the approach will always vary based on the specific organization and the specific project.

Regardless of strict adherence to agile processes, every food manufacturer can benefit from a more agile approach to product development and collaboration.

Across supply chains and customer interactions, there are opportunities for deeper collaboration and a greater focus on industry trends and consumer demands. We’ve purpose-built the Agile Kitchen at Bluegrass to create a space for this collaboration and consultation. It’s a key component of Bluegrass Ingredients’ larger agile approach that we bring to all of our interactions with customers.